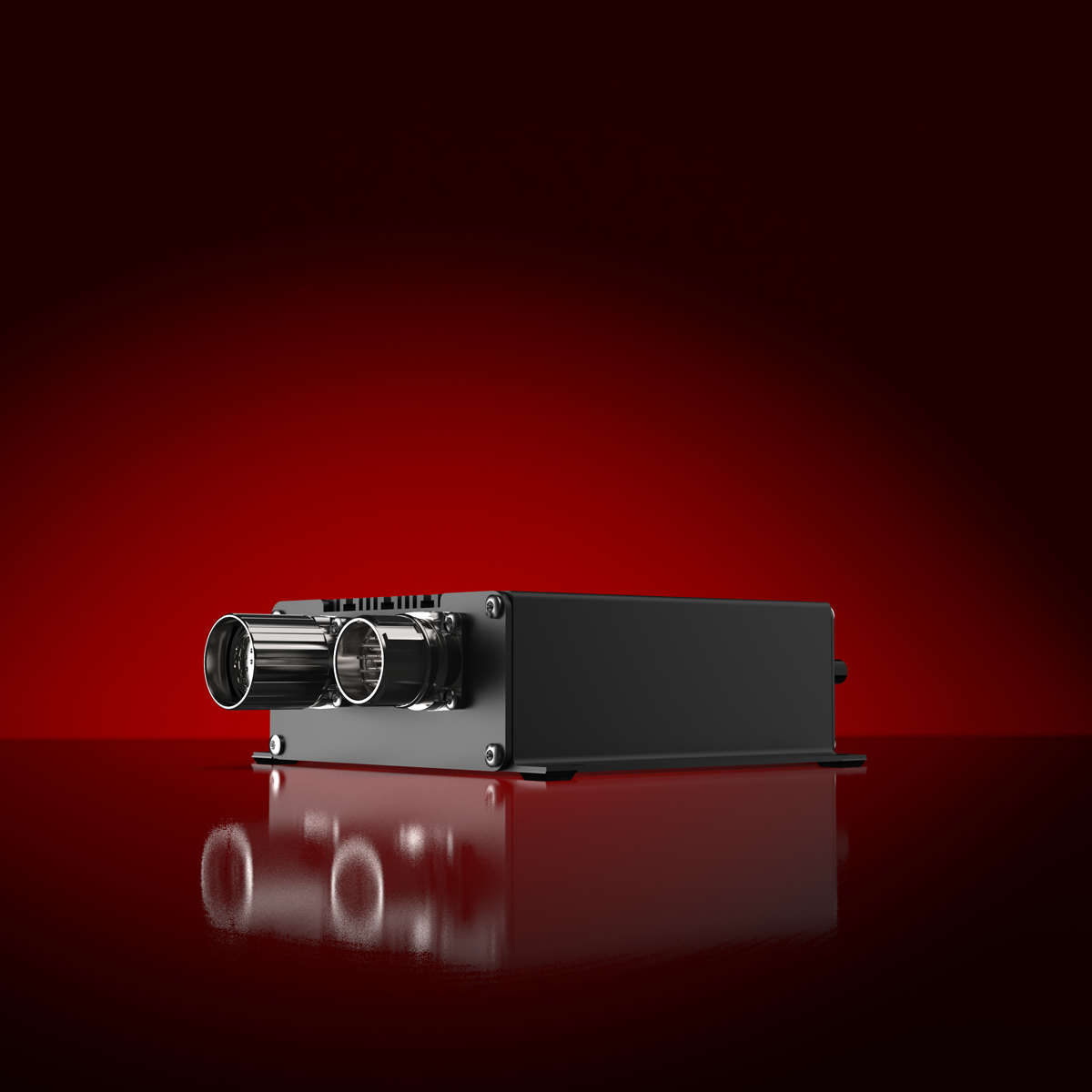

Testing and programming unit GEL 211 B

General information

- Testing any sensors with sin/cos output 1 VPP, e.g. MiniCODER

- Transmitting the data via WLAN to mobile terminals (tablet, PC etc.)

- Display of the data in a web browser, independent of the operating system

Used for checking the signals for compliance with adjustable tolerance limits

- sin/cos signals (amplitude, offset, phase offset)

- Reference signal (amplitude, offset, position and width)

- Target wheel (damage, concentricity, quality of the teeth)

Defining and saving different tolerance limits

MiniCODER plus: Used for setting the parameters

- Automatic calibration of the sin/cos signals

- Configuring/reading the operating hours counter

- Saving the 7 configured speed ranges for the operating hours counter in one record

Possible to save several records in the GEL 211

Features

- Compact device suitable for mobile use

- Data display on terminals with web support

Advantages

- Eases assembly: Due to the fast evaluation of the measured signals, the interactive correction of the signals and the graphic evaluation, the analysis of the signals is extremely straightforward.

- Optimises maintenance and service work: Diagnostics and parameter configuration on the MiniCODER plus are undertaken in the installed state, e.g. without opening the spindle. This aspect is particularly convenient and efficient.

- Increases the reliability: The measured values from the analysis and the spindle histogram are documented automatically by the generation of the report, which can be printed out and saved.

Field of application

- Servicing and commissioning machine tools

- Servicing and commissioning HSC spindles

- Servicing and commissioning motors

- Testing any sensors with sin/cos output 1 VPP, e.g. MiniCODER

- Transmitting the data via WLAN to mobile terminals (tablet, PC etc.)

- Display of the data in a web browser, independent of the operating system

Used for checking the signals for compliance with adjustable tolerance limits

- sin/cos signals (amplitude, offset, phase offset)

- Reference signal (amplitude, offset, position and width)

- Target wheel (damage, concentricity, quality of the teeth)

Defining and saving different tolerance limits

MiniCODER plus: Used for setting the parameters

- Automatic calibration of the sin/cos signals

- Configuring/reading the operating hours counter

- Saving the 7 configured speed ranges for the operating hours counter in one record

Possible to save several records in the GEL 211

Features

- Compact device suitable for mobile use

- Data display on terminals with web support

Advantages

- Eases assembly: Due to the fast evaluation of the measured signals, the interactive correction of the signals and the graphic evaluation, the analysis of the signals is extremely straightforward.

- Optimises maintenance and service work: Diagnostics and parameter configuration on the MiniCODER plus are undertaken in the installed state, e.g. without opening the spindle. This aspect is particularly convenient and efficient.

- Increases the reliability: The measured values from the analysis and the spindle histogram are documented automatically by the generation of the report, which can be printed out and saved.

Field of application

- Servicing and commissioning machine tools

- Servicing and commissioning HSC spindles

- Servicing and commissioning motors

Contact partner

Bill Zhang

Key Account Manager

Product images

Further information